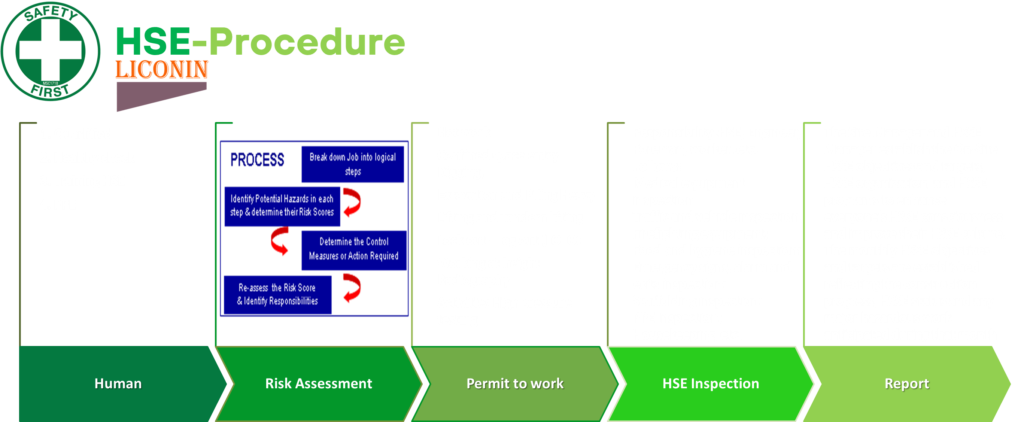

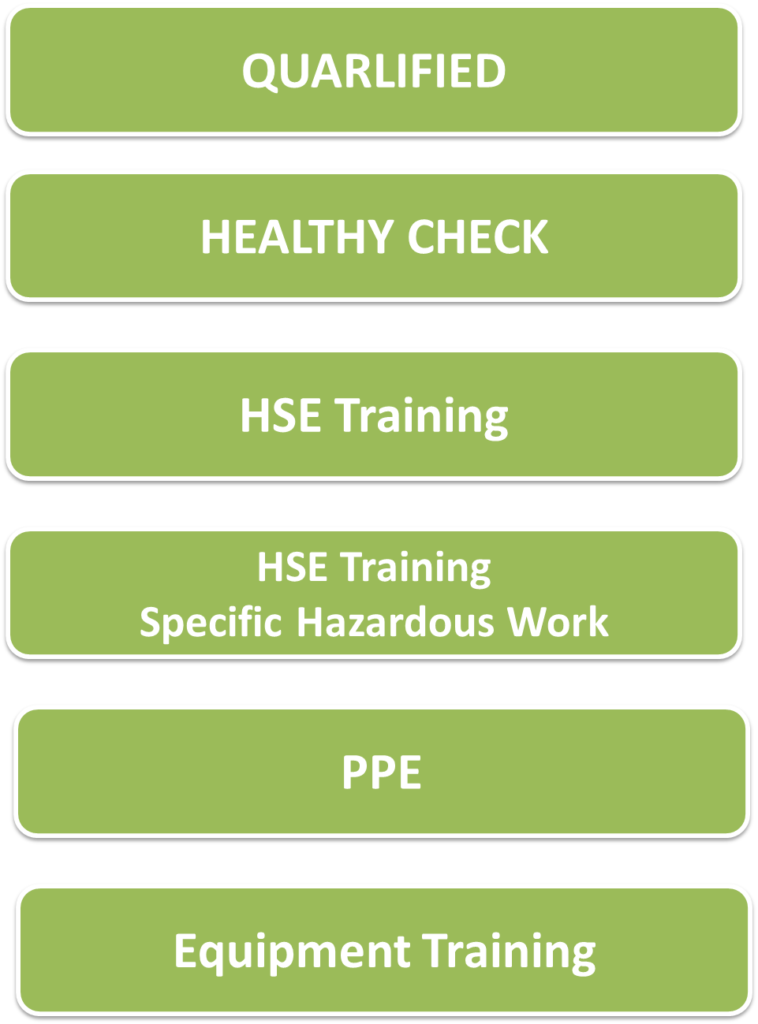

Human

Qualified

Upper 18 old – follow Regulations in Viet Nam

Qualified skills follow the position

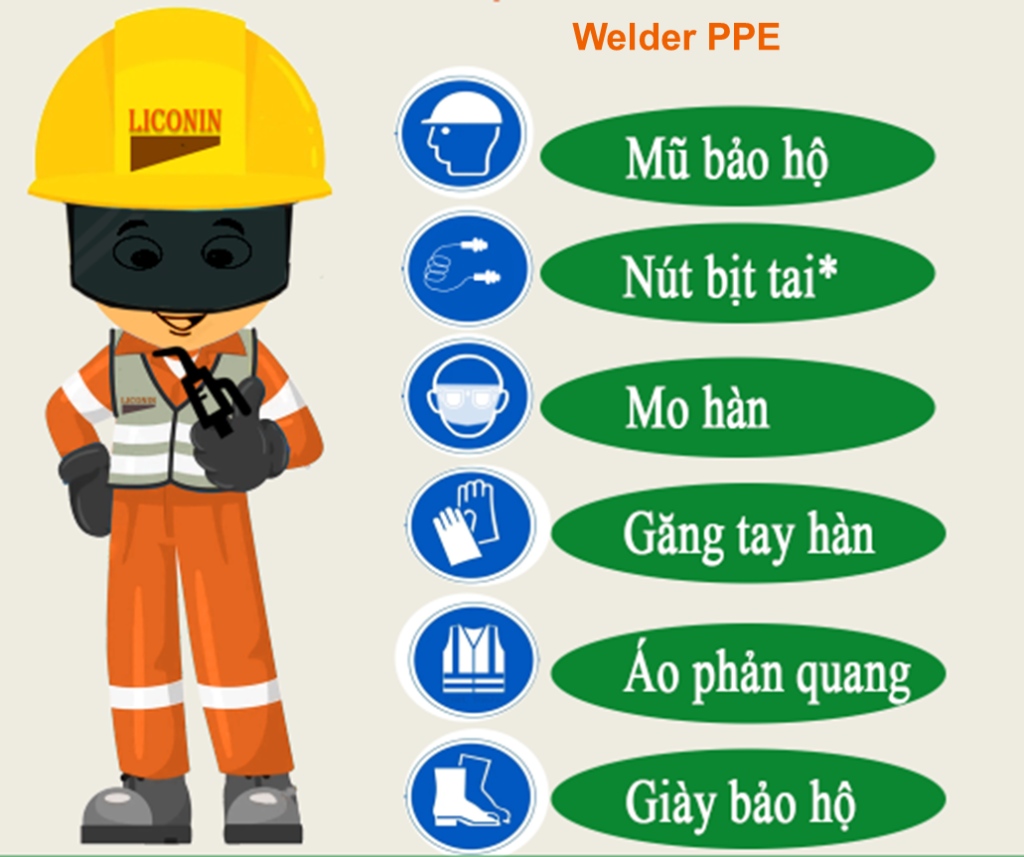

Welder: required certification – testing

Healthy check

Healthy type 1 & 2 for the main job

Healthy type 3 for housekeeping

HSE Training

Required all staff and employees before working on the project

Analyzing the tasks to be performed, identifying and eliminating hazards, and communicating with their crews on how to do the job safely.

HSE Training Specific Hazardous Work

Working at high

Confinder space

Crane operator

Certified Electrician

Rigger

Signal

Certified Electrician

Third-party trained

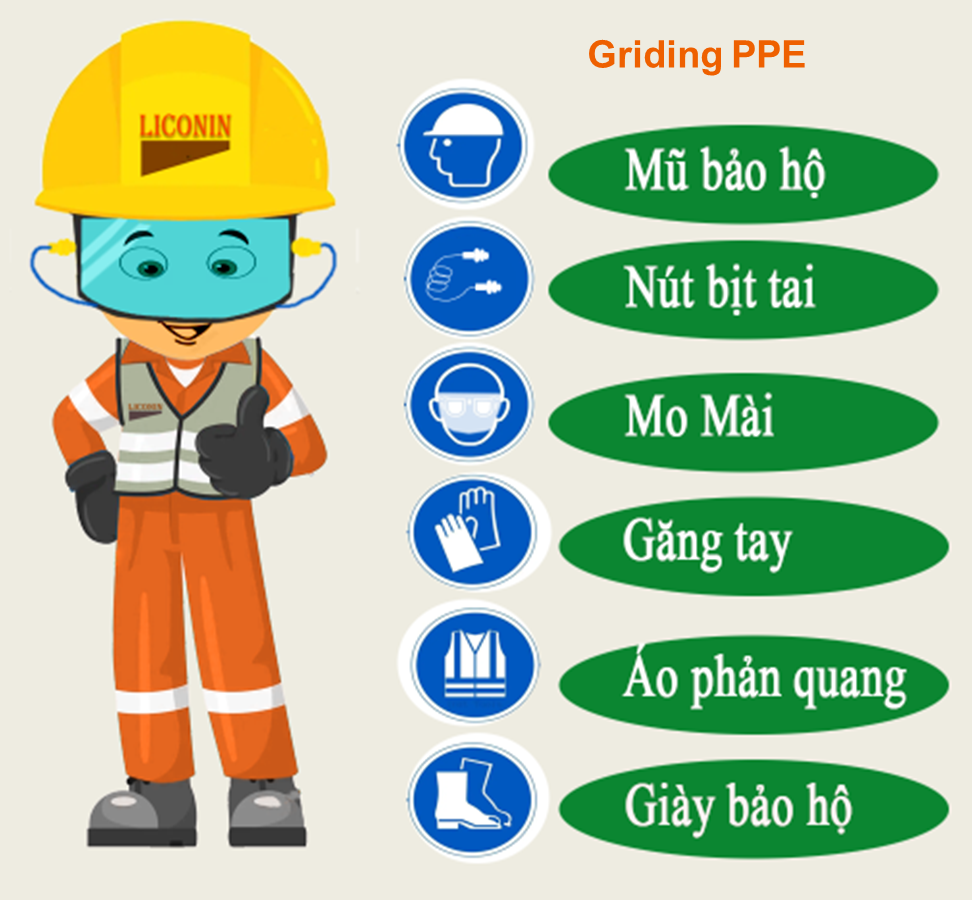

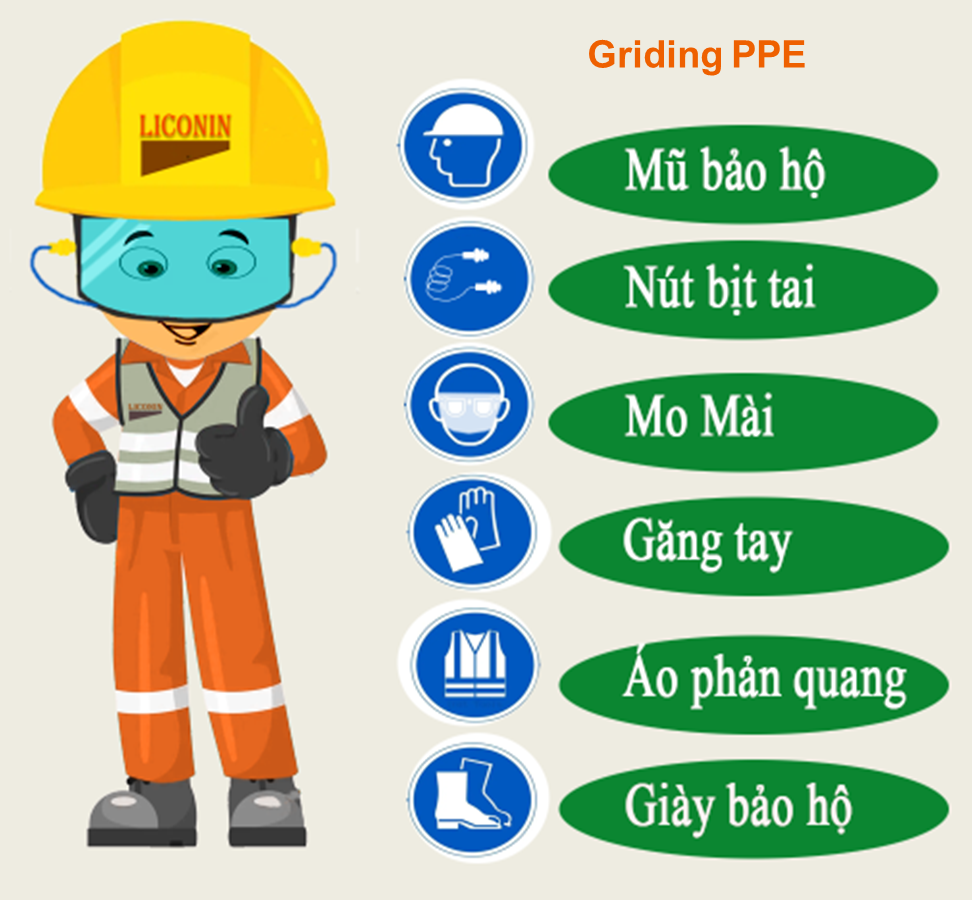

PPE

Equipment Training

Risk Assessment

The Permit to Work

The Permit to Work Procedure and various works subject to the Permit to Work must be established and fully informed to personnel responsible for the work.

Site engineer and Site HSSE Manager are responsible for finalizing a written Permit to Work Procedure describing the following:

Conditions and type of work requiring Permits to Work

Department/ Authority who issues Permits

Deadlines for submissions of applications

Application process/steps

Survey and/or measurements required.

Inspection

Responsibility : HSE team, Engineer team, Foreman, worker….

Follows:

Medical equipment inspection;

Traffic (speed limit) and vehicle inspection;

Firefighting equipment;

Food and hygiene inspection;

Emergency signs, alarm and exits inspection;

Scaffolding inspection;

PPE Inspection;

Housekeeping, etc.

Report

| Sr.No | Item | Frequency | Remarks |

| 1 | HSSEMeetings HSSE Management Meeting | Monthly & as required | SM, CM, HSSEM, Security Manager |

| 2 | Tool Box Meeting | At least Weekly | Supervisor, Foremen, Workers HSSE SVs |

| 3 | STARRT | Daily | Supervisor, Foremen, Workers HSSE SVs |

| 4 | HSSE Training | -Daily or as required | |

| 5 | HSSE Induction Training | -As required | For all new entrants |

| 6 | HSSE Training for Manager | -As required | For Manager and supervisor |

| 7 | HSSE Training for hazards work | -Every Six months | For Employees involved in |

| 8 | Fire and First-aid Training | -Every Six months | For all HSSE personnel |

| 9 | Evacuation/Rescue Training | For emergency response team | |

| 10 | Housekeeping Waste disposal | Daily as required | By every work crew after day`s work By designated disposal date/time |

| 11 | Equipment Inspection | At bringing onto site and Periodically | By LICONIN M&E inspectors |

| 12 | General Safety Inspection | Daily | By supervisors/foremen, HSSE Staff |

| 13 | Planned Safety Inspection | Weekly | By CM, Const. SVs, and other assigned |

| 14 | Official HSSE Audit | Every six Months | By Senior management |

| 15 | Permit to Work | Daily or as required | For designated work or location |

| 16 | General Promotion | According program | Groups or individuals contributed to HSSE Performances |

| 17 | Safety Incentive Awards | According program | |

| 18 | Sanitation & Health Service | As required | For employee involved in health hazards |

| 19 | Physical Examination | Monthly | Quality test by authorized laboratory |

| 20 | Potable Water | Monthly | Camp Manager, HSSE SVs |

| 21 | Camps, Kitchen & Toilets | Weekly | HSSE SVs |

| 22 | On-Site Toilets | Weekly | HSSE SVs |

| 23 | Reporting | ||

| 24 | Daily HSSE Report | Daily | From HSSE SVs to HSSEM |

| 25 | Monthly HSSE Report | Monthly | From HSSEM to SM and to PM |

| 26 | Monthly Statistics Report | Monthly | From HSSEM to SM and to PM |

| 27 | HSSE Inspection Report | As required | From Inspectors to HSSEM, CMs |

| 28 | HSSE Audit Report | Every six months | From Auditors to PM, SM, HSSEM |

| 29 | Training Report | Monthly | From trainer to HSSEM |

| 30 | Accident Report | Immediately, timely | From SM/HSSEM to PM |